The Benefits of Purchasing Screw Feeding Conveyor

♦ EP regards quality as the lifeline of the enterprise and is committed to providing customers with the best quality products and services. Through strict quality management system and standardized production process, to ensure that each mixing station has been strictly tested, in line with high quality standards.

♦ Transparent service process, customers can know the progress of the service at any time, enhance trust. Pay attention to customer feedback, and constantly optimize the service content and quality to better meet customer needs.

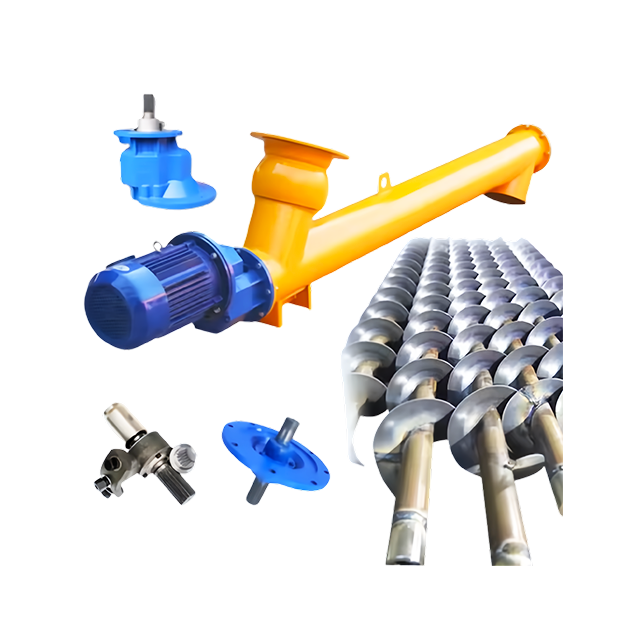

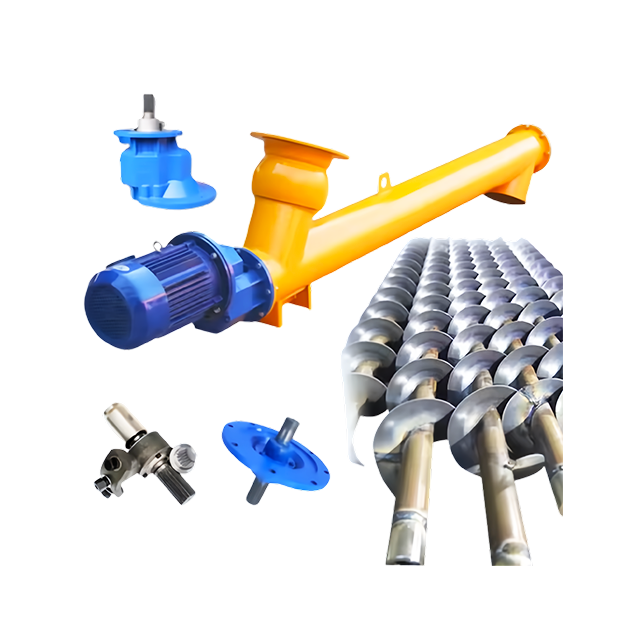

♦ Provide professional technical support to ensure that the equipment maintains the best performance during use and reduces the occurrence of failures. Spare parts supply guarantee to ensure that your equipment gets the best support and protection to extend the service life.

♦ Efficient material handling. Screw conveyor adopts spiral conveyor elements, which can continuously and stably transport various types of powder, granular or small pieces of material. Whether it is fly ash, grain, chemicals or building materials, screw feeder machines are able to efficiently transport materials from one place to another, avoiding the high labor intensity and inefficiency of traditional manual handling.

♦ Space saving and easy installation. Compared with other types of conveying equipment, screw conveyors are compact in design and can save a lot of installation space. The trough of screw conveyor can be installed under the ground or on the ceiling, suitable for limited space environment. Its simple structure makes installation and maintenance more convenient and reduces the complexity of operation and management.

♦ Strong adaptability, can handle a variety of materials. Whether it is dry, wet material, or sticky material, screw conveyor can effectively handle. flex screw conveyor is one of the most adaptable devices on the market and can easily handle materials of different shapes and densities. Especially in the food, fertilizer, mineral and chemical industries, the adaptability of the screw conveyor greatly improves the efficiency of the production line.

♦ Low maintenance costs. The mechanical structure of the screw conveyor is relatively simple and has a long service life, so the daily maintenance and maintenance costs are relatively low. By regularly checking the screw blades, drive system and bearings, users can ensure the long-term stable operation of the screw conveyor and avoid frequent equipment failures.

♦ Automated control and precise delivery. Screw feeder machines excel in automated systems, delivering materials precisely according to set delivery speeds and volumes. By combining with an automated control system (such as PLC control), the screw conveyor can efficiently perform quantitative conveying tasks and improve the overall automation level of the production line.

♦ Flexible installation and custom design. Flex screw conveyor provides greater installation flexibility and is especially suitable for multi-angle, multi-direction material handling needs. According to different operating environments and material properties, screw conveyors can be customized according to customer needs, including different materials, screw blade shape, conveying length, etc., to ensure the best fit.

Parameters of Screw Feeding Conveyor

|

Diameter of outer pipe |

Diameter of inlet flange (mm) | Height of inlet (H1) | Height of outlet (H2) | ||||||

| 0-20º | >20-40º | >40-50º | 0-20º | >20-40º | >40-50º | ||||

| A | B | C | H1 | H1 | H1 | H2 | H2 | H2 | |

| Ø 140mm | 200 | 250 | 280 | 400 | 450 | 500 | 250 | 300 | 350 |

| Ø 168mm | 200 | 250 | 280 | 400 | 450 | 500 | 250 | 300 | 350 |

| Ø 219mm | 300 | 350 | 380 | 500 | 550 | 600 | 300 | 400 | 450 |

| Ø 273mm | 300 | 350 | 380 | 500 | 600 | 700 | 350 | 450 | 500 |

| Ø 323mm | 300 | 350 | 380 | 550 | 700 | 800 | 400 | 500 | 600 |

| Ø 407mm | 470 | 470 | 530 | 750 | 900 | 1000 | 450 | 600 | 700 |